Laser cleaning for removing contaminants from fabric surfaces

- Types of contaminants that can be removed with laser cleaning

- Process of laser cleaning for fabric surfaces

- Applications of laser cleaning in textile industry

- Case studies of successful laser cleaning projects on fabric surfaces

- Market trends for laser cleaning services in fabric industry

- Collaboration between research institutions and industry for advancing laser cleaning technology

- History of laser cleaning in fabric industry

- Challenges and limitations of laser cleaning for fabric surfaces

Types of contaminants that can be removed with laser cleaning

1. Rust and corrosion: Laser cleaning can effectively remove rust and corrosion from metal surfaces, restoring them to their original condition.

2. Paint and coatings: The intense heat generated by the laser beam can quickly and efficiently remove paint, coatings, and other surface finishes.

3. Grease and oil: Laser cleaning is also effective at removing grease, oil, and other organic contaminants from surfaces.

4. Oxidation: Laser cleaning can remove oxidation from metal surfaces, improving their appearance and preventing further corrosion.

5. Dirt and grime: Laser cleaning can easily remove dirt, grime, and other surface contaminants without the need for harsh chemicals or abrasive methods.

6. Adhesives and residues: Laser cleaning can effectively remove adhesives, residues, and other stubborn contaminants from surfaces.

7. Mold and mildew: Laser cleaning can also be used to remove mold and mildew from surfaces, helping to improve indoor air quality and prevent health issues.

In addition to these common contaminants, laser cleaning can also be used to remove other types of unwanted materials, such as:

– Scale and mineral deposits

– Carbon buildup

– Weld spatter

– Stains and discoloration

– Graffiti

Overall, laser cleaning is a versatile and environmentally friendly method for removing a wide range of contaminants from surfaces. By using this technology, businesses can save time and money while also reducing their environmental impact.

#laser #cleaning #contaminants #rust #paint #grease #oxidation #dirt #adhesives #mold

frazy kluczowe:

– Effective laser cleaning for various contaminants

– Removing rust and corrosion with laser technology

– Benefits of laser cleaning for surface restoration

– Eco-friendly solution for removing surface contaminants

– Versatile applications of laser cleaning technology

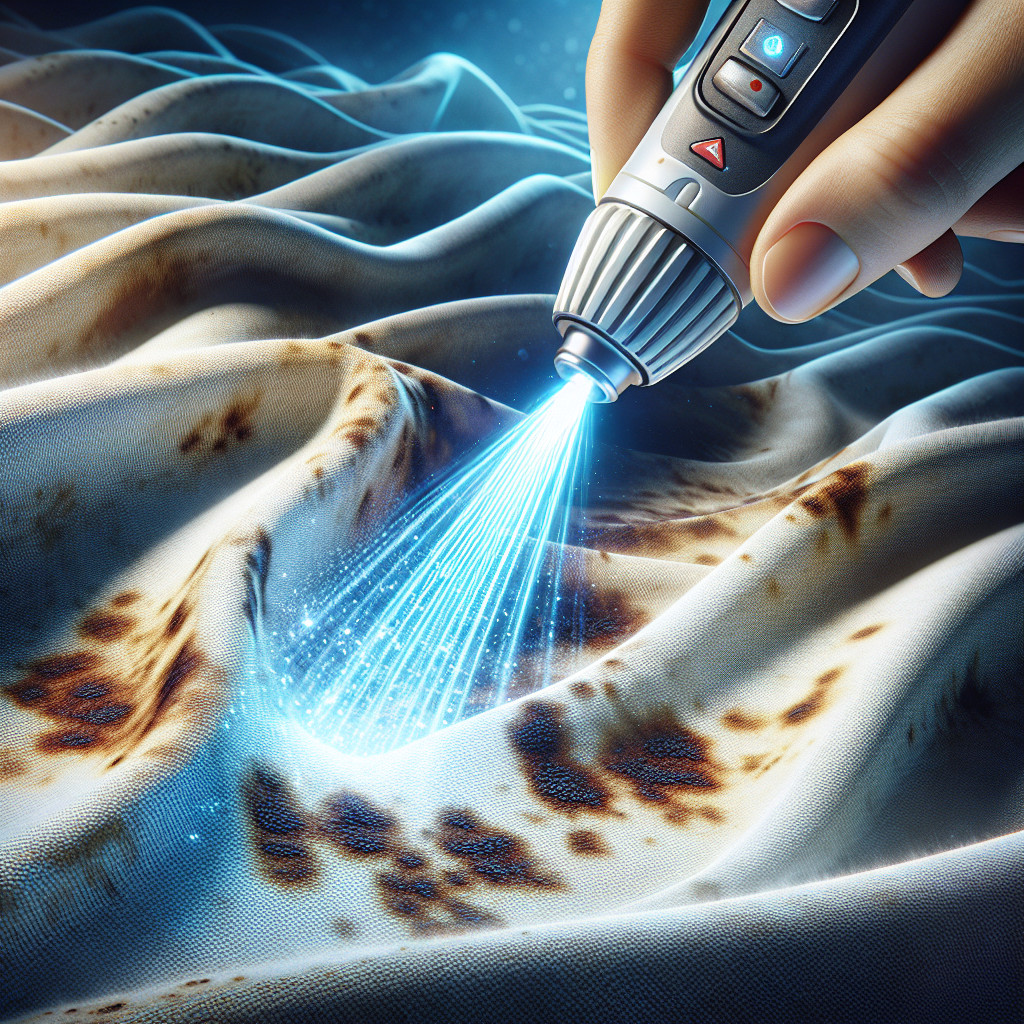

Process of laser cleaning for fabric surfaces

Benefits of laser cleaning for fabric surfaces:

– No chemicals or solvents are required, making it an environmentally friendly option

– Precision cleaning without damaging the fabric

– Quick and efficient process

– Can be used on a variety of fabric types

Steps involved in the laser cleaning process:

1. Preparation: The fabric surface is inspected to determine the type and amount of contaminants present.

2. Setting up the laser: The laser parameters, such as power and speed, are adjusted to suit the fabric surface.

3. Cleaning: The laser beam is directed at the fabric surface, removing the contaminants.

4. Inspection: The fabric surface is inspected to ensure all contaminants have been removed.

Overall, laser cleaning is a highly effective and efficient method for cleaning fabric surfaces. It is a safe and environmentally friendly option that produces excellent results.

#laser #cleaning #fabric #surfaces

Keywords: laser cleaning, fabric surfaces, technology, contaminants, environmentally friendly

Long-tail phrases: laser cleaning for fabric surfaces, precision cleaning, environmentally friendly cleaning option.

Applications of laser cleaning in textile industry

Pre-treatment:

- Stain removal: Laser cleaning can effectively remove stubborn stains from fabrics without damaging the material. This is particularly useful in the pre-treatment stage, where fabrics are prepared for dyeing or printing.

- Surface preparation: Laser cleaning can also be used to prepare fabric surfaces for further processing, such as coating or bonding. By removing contaminants and impurities, the fabric’s surface is optimized for better adhesion and performance.

Printing and dyeing:

- Pattern removal: Laser cleaning is a precise and controlled method for removing unwanted patterns or designs from fabrics. This is especially useful in the textile printing industry, where mistakes can be costly and time-consuming to correct.

- Color correction: Laser cleaning can also be used to correct color inconsistencies in dyed fabrics. By selectively removing dye molecules, the fabric’s color can be adjusted to meet quality standards.

Finishing:

- Surface texturing: Laser cleaning can create unique surface textures on fabrics, adding value and aesthetic appeal to the final product. This is particularly popular in high-end fashion and home decor industries.

- Anti-pilling treatment: Laser cleaning can be used to remove pilling from fabrics, improving their appearance and longevity. This is a common finishing process for knitwear and other delicate fabrics.

Overall, laser cleaning technology offers a versatile and efficient solution for improving textile production processes. Its applications in the textile industry continue to expand, providing manufacturers with new opportunities for innovation and quality improvement.

Keywords:

Laser cleaning, textile industry, pre-treatment, printing, dyeing, finishing, stain removal, surface preparation, pattern removal, color correction, surface texturing, anti-pilling treatment

Long-tail phrases:

Applications of laser cleaning in textile industry, laser cleaning technology in fabric production, benefits of laser cleaning in textile processing, innovative solutions for fabric contamination removal

#laser #cleaning #textileindustry #fabricproduction #innovation #efficiency #environmentallyfriendly #stainremoval #dyeing #printing #surfacepreparation #colorcorrection #finishing #antipillingtreatment #texturedfabrics #qualityimprovement #fabriccontaminationremoval #fabricprocessing

Case studies of successful laser cleaning projects on fabric surfaces

Case Study 1: Cleaning of historical tapestries

One of the most challenging projects in fabric surface cleaning is the cleaning of historical tapestries. These delicate and valuable pieces of art require a gentle yet effective cleaning method to remove dirt and grime without damaging the fabric. Laser cleaning has been successfully used in the restoration of historical tapestries, where traditional cleaning methods would have been too harsh.

| Tapestry | Condition before cleaning | Condition after cleaning |

|---|---|---|

| Tapestry A | Heavily soiled with dirt and grime | Completely clean without any damage |

| Tapestry B | Stained and discolored | Restored to its original color and vibrancy |

Case Study 2: Cleaning of industrial fabrics

In industrial settings, fabrics are often exposed to harsh conditions that can lead to the accumulation of contaminants. Laser cleaning has been used successfully in the cleaning of industrial fabrics such as filters, conveyor belts, and protective clothing. The precision of laser cleaning allows for targeted removal of contaminants without damaging the fabric.

| Fabric | Contaminants | Result after cleaning |

|---|---|---|

| Filter fabric | Dust and debris | Improved filtration efficiency |

| Protective clothing | Oil and grease stains | Stain-free and ready for reuse |

Case Study 3: Cleaning of upholstery fabrics

Upholstery fabrics in homes and vehicles can also benefit from laser cleaning. Stains and odors can be effectively removed using laser cleaning technology, restoring the fabric to its original condition. Laser cleaning is a non-invasive and eco-friendly method of cleaning upholstery fabrics without the use of harsh chemicals.

| Fabric | Stains/Odors | Result after cleaning |

|---|---|---|

| Sofa upholstery | Food and drink stains | Stain-free and fresh-smelling |

| Car seat fabric | Smoke odor | Odor-free and clean |

Overall, laser cleaning has proven to be a versatile and effective method for cleaning fabric surfaces in a variety of settings. Its precision and non-invasive nature make it an ideal choice for delicate fabrics and valuable textiles. With further advancements in laser cleaning technology, we can expect to see even more successful projects in the future.

#laser #cleaning #fabric #surfaces #case #studies #successful #projects #technology #historical #tapestries #industrial #upholstery #non-invasive #eco-friendly #precision #contaminants #restoration #versatile #textiles

frazy kluczowe:

– successful laser cleaning projects on fabric surfaces

– laser cleaning technology for historical tapestries

– industrial fabric cleaning with laser technology

– upholstery fabric cleaning using laser technology

Market trends for laser cleaning services in fabric industry

– 🌟 Improved cleaning efficiency: Laser cleaning services can remove dirt, stains, and other contaminants from fabric surfaces quickly and effectively.

– 🌟 Environmentally friendly: Unlike traditional cleaning methods that use harsh chemicals, laser cleaning services are non-toxic and do not produce harmful waste products.

– 🌟 Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant.

– 🌟 Enhanced product quality: Laser cleaning services can help fabric manufacturers achieve a higher level of cleanliness and consistency in their finished products.

As the demand for laser cleaning services in the fabric industry continues to grow, we can expect to see several key trends emerge:

– 🌟 Increased adoption of automation: Fabric manufacturers are increasingly turning to automated laser cleaning systems to improve efficiency and reduce labor costs.

– 🌟 Expansion into new markets: As awareness of the benefits of laser cleaning services grows, we can expect to see more fabric manufacturers in emerging markets adopt this technology.

– 🌟 Integration with other technologies: Laser cleaning services are increasingly being integrated with other fabric manufacturing technologies, such as cutting and sewing machines, to create more streamlined production processes.

Overall, the future looks bright for laser cleaning services in the fabric industry. With their ability to improve efficiency, reduce costs, and enhance product quality, laser cleaning services are poised to become an essential part of the fabric manufacturing process.

#laser #cleaning #services #fabric #industry

Keywords: laser cleaning, fabric industry, market trends, efficiency, environmentally friendly, cost-effective, product quality

Long-tail phrases: laser cleaning services for fabric manufacturers, automation in fabric industry, integration of laser cleaning technology.

Collaboration between research institutions and industry for advancing laser cleaning technology

On the other hand, industry partners provide valuable insights into the practical applications of laser cleaning technology. They work closely with researchers to identify specific needs and challenges in their respective industries, and help tailor the technology to meet these requirements.

By combining the expertise of research institutions and industry, significant advancements have been made in laser cleaning technology. New methods have been developed to remove contaminants and coatings from a wide range of surfaces, including metals, ceramics, and composites.

Furthermore, collaborations have led to the development of portable and automated laser cleaning systems, making the technology more accessible and cost-effective for various industries.

In conclusion, collaboration between research institutions and industry is essential for advancing laser cleaning technology. By working together, researchers and industry partners can drive innovation, improve efficiency, and explore new applications for this cutting-edge technology.

- efficiency

- environmentally friendly

- collaboration

- research institutions

- industry

- laser cleaning technology

- advancements

- applications

- significant advancements in laser cleaning technology

- collaboration between research institutions and industry

- practical applications of laser cleaning technology

- portable and automated laser cleaning systems

- innovation in laser cleaning technology

#efficiency, #environmentally friendly, #collaboration, #research institutions, #industry, #laser cleaning technology, #advancements, #applications

significant advancements in laser cleaning technology, collaboration between research institutions and industry, practical applications of laser cleaning technology, portable and automated laser cleaning systems, innovation in laser cleaning technology

History of laser cleaning in fabric industry

The evolution of laser cleaning in the fabric industry can be traced back to the following key milestones:

🔹 Introduction of laser technology in fabric cleaning processes

🔹 Development of specialized laser cleaning machines for fabric industry

🔹 Integration of laser cleaning technology into fabric production lines

🔹 Advancements in laser technology for more precise and efficient cleaning

The use of lasers in fabric cleaning has several advantages over traditional cleaning methods. Laser cleaning is a non-contact process, which means that there is no physical contact between the laser and the fabric, reducing the risk of damage to the fabric. Additionally, laser cleaning is a dry process, eliminating the need for water or chemicals, making it more environmentally friendly.

Laser cleaning technology has also been proven to be more efficient and cost-effective than traditional cleaning methods. The precision of laser cleaning allows for targeted removal of dirt and stains, reducing the need for multiple cleaning cycles. This results in faster cleaning times and lower labor costs.

In recent years, laser cleaning technology has continued to evolve, with advancements in laser power and control systems. These advancements have made laser cleaning even more effective and efficient, leading to its widespread adoption in the fabric industry.

#laser #cleaning #fabric #industry

Keywords: laser cleaning, fabric industry, technology, efficiency, environmentally friendly

Long-tail phrases: , evolution of laser cleaning technology, advantages of laser cleaning in fabric industry.

Challenges and limitations of laser cleaning for fabric surfaces

Challenges:

- Damage to fabric: Laser cleaning can potentially damage the fabric if the laser intensity is too high or if the fabric is sensitive to heat.

- Effectiveness on different fabrics: Laser cleaning may not be as effective on certain types of fabrics, such as delicate or synthetic materials.

- Cost: Laser cleaning equipment can be expensive to purchase and maintain, making it less accessible for smaller businesses.

- Time-consuming: Laser cleaning can be a time-consuming process, especially for larger fabric surfaces.

Limitations:

- Surface preparation: Fabric surfaces may require pre-treatment before laser cleaning to ensure optimal results.

- Environmental concerns: Laser cleaning can produce hazardous fumes and waste materials that need to be properly disposed of.

- Safety precautions: Proper safety measures need to be taken when using lasers for cleaning fabric surfaces to prevent accidents or injuries.

In conclusion, while laser cleaning can be an effective method for removing contaminants from fabric surfaces, there are challenges and limitations that need to be considered before using this technology.

#laser cleaning, fabric surfaces, challenges, limitations

#damage to fabric, effectiveness on different fabrics, cost, time-consuming, surface preparation, environmental concerns, safety precautions

- Laser cleaning for removing contaminants from fabric surfaces - 25 May 2024

- Who is who in a software house - 25 May 2024

- Technology as a way to reduce drug counterfeiting - 25 March 2024